Engineers are recently designing a PV DC line of smart distributed energy resources with DC 1500V to increase power generation efficiency.

The increased generation voltage is certainly attractive, but insulation rating of the entire PV system must be increased, and the associated equipment must be able to operate at higher voltages.

A DC voltage sensor with insulation amplifier technology, J&D’s new technology designed for high withstand voltage and stability, and a DC current sensor certified to IEC61010-1 PD2 CAT III can realize more accurate power efficiency measurement.

This article was originally published in Smart Energy International Issue 4-2021.

Read the mobile-friendly digital magazine or subscribe to receive a print copy

Recently, J&D designed a voltage and current sensor that provides high-insulation technology capable of withstanding 1500V and implemented high-precision characteristics by using an ultra-precision Zero-Drift Op Amp.

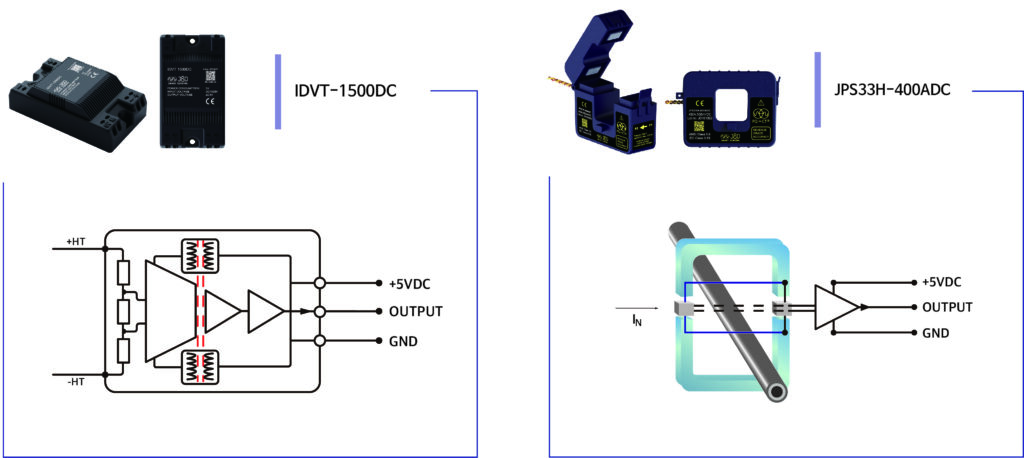

1. DC 1500V high accuracy voltage sensor; IVDT-series

Hybrid design using reinforced isolation amplifier technology and Ultra Precision Zero-Drift Op Amps.

Temperature of the Solar power usually rises to 40˚ C on a summer day.

In addition, the temperature inside the Distribution board can reach 100˚C in the worst case.

Therefore, the voltage sensor must remain accurate even at these high temperatures. J&D’s voltage sensor was developed with high voltage isolation reinforced amplifier technology.

Voltage Sensors – IDVT series begins with an internal High Voltage resistor network. This network measures DC Voltage by directly contacting both the Positive High Voltage (+HT) and the Negative High Voltage signal is transmitted to the secondary side of the sensor through an insulated Reinforced transformer that isolates the Primary High Voltage from the Secondary Low Voltage.

The resulting signal is converted through an auto-zeroing techniques amplifier into either Voltage signal.

Therefore, the circuit converts a primary Voltage into a secondary Voltage that is proportional to the input.

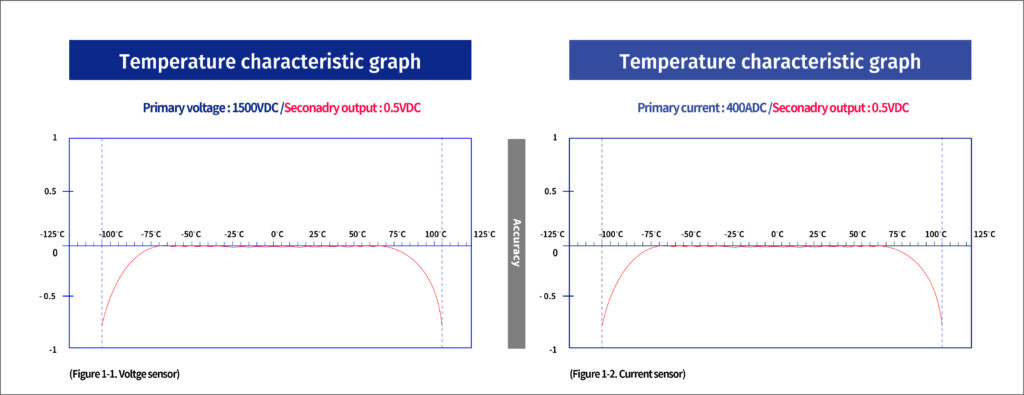

The reinforced isolation amplifier technology and the hybrid design using Ultra Precision Zero-Drift Op Amps not only maintain high accuracy at high temperatures, but also achieve accuracy with 5V to 30V free wide range voltage. When you refer to Figure 1-1, you find that the Voltage sensor can provide high precision despite high temperature.

Features:

(1) Power consumption: 5V

(2) Input voltage: DC 1500V

(3) Output voltage: ±0.5V

(4) Accuracy: 0.5%

(5) Ambient Operating temperature: -40˚ to +105˚

2: High-insulation and High-accuracy current sensor JPS-H Series for DC 1500V power line monitoring. Temperature Reinforced Amplifier Technology.

J&D, the first in the world, has developed a product designed with high insulation so that it can be used stably in the DC 1500V line.

JPS-H is a sensor that develops input voltage from 600V to 1500V and is a product that has obtained PD2 certification and CAT III 1500V certification of IEC-61010-1.

JPS-H series begins with an internal Insulation distance design split core technology network.

This network is measured using two hall elements and a permalloy core based on advanced open loop technology and the resulting signal is then converted through an auto-zeroing techniques amplifier into either Voltage signal.

A split-core sensor that can be easily installed on a cable and designed by hybridizing Hall element twin technology and Ultra Precision Zero-Drift Op Amps is designed to maintain high precision even at high temperature.

This can solve problems of high operating temperatures because it is installed where solar power is maximized for the best energy capture performance due to the feature of the PV system.

An accuracy of 0.5% can be achieved even with a low power consumption which is 5V to 30V free wide voltage. Also, Figure 1-2 shows high accuracy of current measurement is possible even with high temperatures.

Features:

(1) Power consumption: 5V

(2) Rated current: DC 400A

(3) Output voltage: ±0.5V

(4) Accuracy: 0.5%

(5) Ambient Operating temperature: -40˚ to +105˚

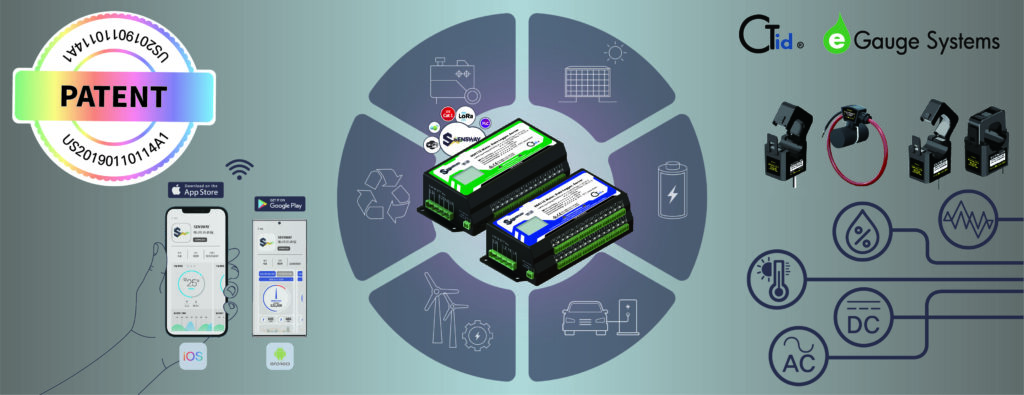

3: J&D’s options: CTid technology that can be monitored by UI

Increasing demand for green energy is one of the driving forces behind the adoption of PV DC1500V power.

In addition, as the amount of energy supplied from renewable energy such as PV power increases, power lines must be measured in high-quality efficiency and critical power protection is always important for abnormal situations, from solar panels to PV inverter systems. Solar panels commonly use a PV Inverter that works with the DC-DC converter to connect the generated power to the grid.

However, a common problem of power electronics is the generation and emission of harmonic currents, which dramatically reduce the quality of the injected current. To identify this issue, it is very important to measure the power quality and efficiency by measuring the voltage and current of the DC 1500V line.

In addition, one of the main considerations for converting primary voltage and current from DC to AC using PV inverters is to ensure system reliability and safety under all environmental conditions.

The voltage and current sensors for the upgraded DC1500V power line are now available in conjunction with eGauge meters. Also, the voltage and current sensors are now available with eGauge’s CTid technology as an option.

If you use the gateway AC/DC energy meter with the CTid technology of eGauge, IDVT series of voltage sensors with built-in CTid technology, and JPS-H series of current sensors, you can operate a solar power plant with more stable power generation.